Best Price on Tungsten Carbide Wire Drawing Dies - Carbide CNC Indexable Inserts – Fotma

Best Price on Tungsten Carbide Wire Drawing Dies - Carbide CNC Indexable Inserts – Fotma Detail:

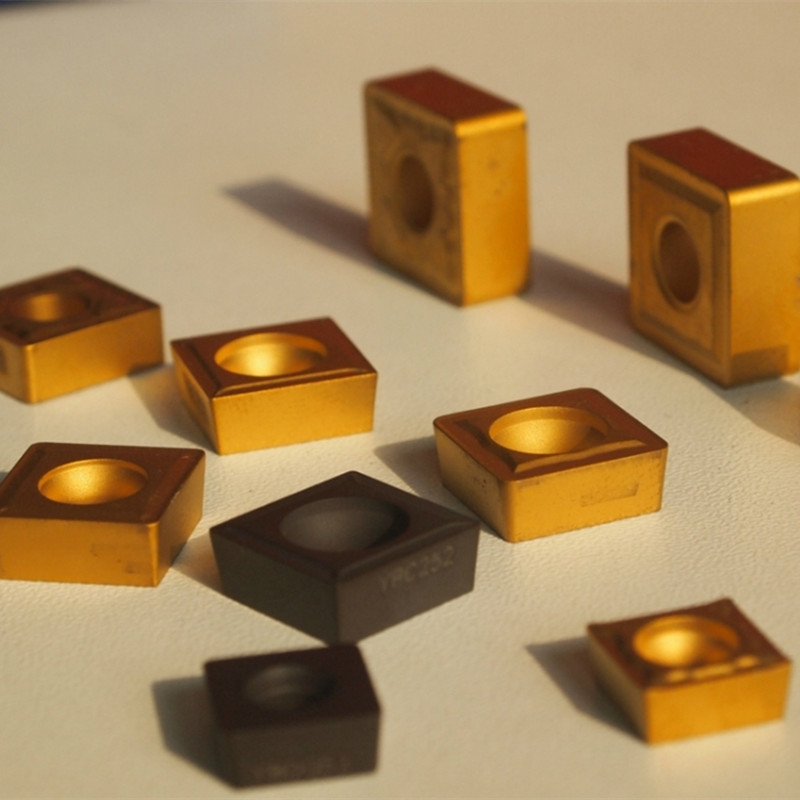

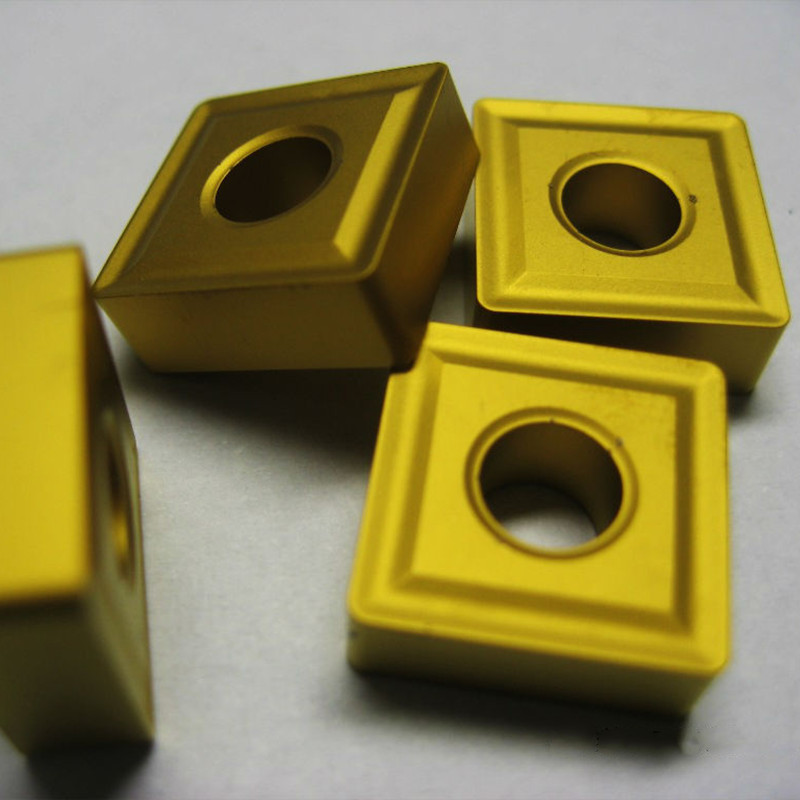

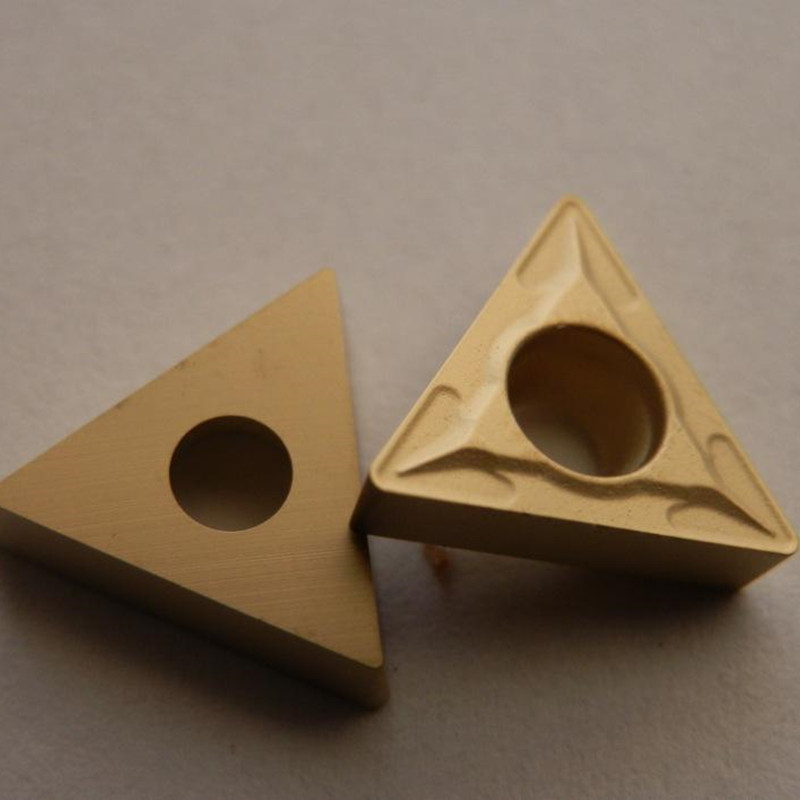

Cemented carbide CNC inserts are mainly made of solid carbide as the base body, and are processed through multiple production processes.

Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide + cobalt powder after mixing by formula and sintering. It has high hardness, high strength, high wear resistance and high elastic modulus. It belongs to the powder metallurgy industry. . As the teeth of modern industry, carbide cutting tools play a fundamental role in promoting the development of the manufacturing industry.

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remain basically unchanged even at a temperature of 500 °C , still has high hardness at 1000℃.

Application:

Carbide Inserts are widely used for cutting, milling, turning, woodworking, grooving etc.

Made by high quality virgin tungsten carbide raw materials. Good quality surface treating and TiN coating.

Our company has in its possession an advanced production line for manufacturing dies and moulds and a production line for post machined cemented carbide products. We can also supply tailor-made products of various specifications based on the requirements of our customers.

Cemented Carbide Grades for CNC Indexable Inserts.

|

Grade |

Applications |

|

C2 Uncoated |

High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron. |

|

C5 Uncoated |

Excellent in strength, impact resistance and resistance to thermal shock ; Rough turning, rough planing and semi planing of Carbon steel and alloy steel. |

|

ZK10UF |

Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. |

|

ZK30UF |

Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. |

|

ZP25 |

Fine in wear resistance and toughness; Rough turning, milling, planing and depth drilling of carbon steel, cast steel, manganese steel and alloy steel. |

|

ZP35 |

A versatile grade, high in red hardness, strength and resistance to impact and thermal shocking. Roughing and strong cutting of steel and cast steel. |

|

Suggestion: We would like to recommend suitable grade depending on your machining materials. |

|

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Best Price on Tungsten Carbide Wire Drawing Dies - Carbide CNC Indexable Inserts – Fotma , The product will supply to all over the world, such as: Accra, Angola, Burundi, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.