Discount Price Precision Machining Components - CMC CuMoCu Heat Sink – Fotma

Discount Price Precision Machining Components - CMC CuMoCu Heat Sink – Fotma Detail:

CMC CuMoCu Material Application

Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc.

Heat sink material on aircraft, heat sink material on radar.

CMC Heat Sink Advantages

1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding strength between molybdenum and copper is excellent, So that the finished material has the lowest thermal expansion coefficient and the best thermal conductivity;

2. The molybdenum-copper ratio of CMC is very good, and the deviation of each layer is controlled within 10%; SCMC material is a multi-layer composite material. The structural composition of the material from top to bottom is: copper sheet – molybdenum sheet – copper sheet – molybdenum sheet… copper sheet, it can be composed of 5 layers, 7 layers or even more layers. Compared with CMC, SCMC will have the lowest thermal expansion coefficient and the highest thermal conductivity.

Grade of CMC Cu-Mo-Cu Materials

| Grade | Density g/cm3 | Coefficient of thermal Expansion ×10-6 (20℃) | Thermal conductivity W/(M·K) |

| CMC111 | 9.32 | 8.8 | 305(XY)/250(Z) |

| CMC121 | 9.54 | 7.8 | 260(XY)/210(Z) |

| CMC131 | 9.66 | 6.8 | 244(XY)/190(Z) |

| CMC141 | 9.75 | 6 | 220(XY)/180(Z) |

| CMC13/74/13 | 9.88 | 5.6 | 200(XY)/170(Z) |

| Material | Wt% Molybdenum Content | g/cm3 Density | Thermal conductivity at 25℃ | Coefficient of thermal Expansion at 25℃ |

| S-CMC | 5 | 9.0 | 362 | 14.8 |

| 10 | 9.0 | 335 | 11.8 | |

| 13.3 | 9.1 | 320 | 10.9 | |

| 20 | 9.2 | 291 | 7.4 |

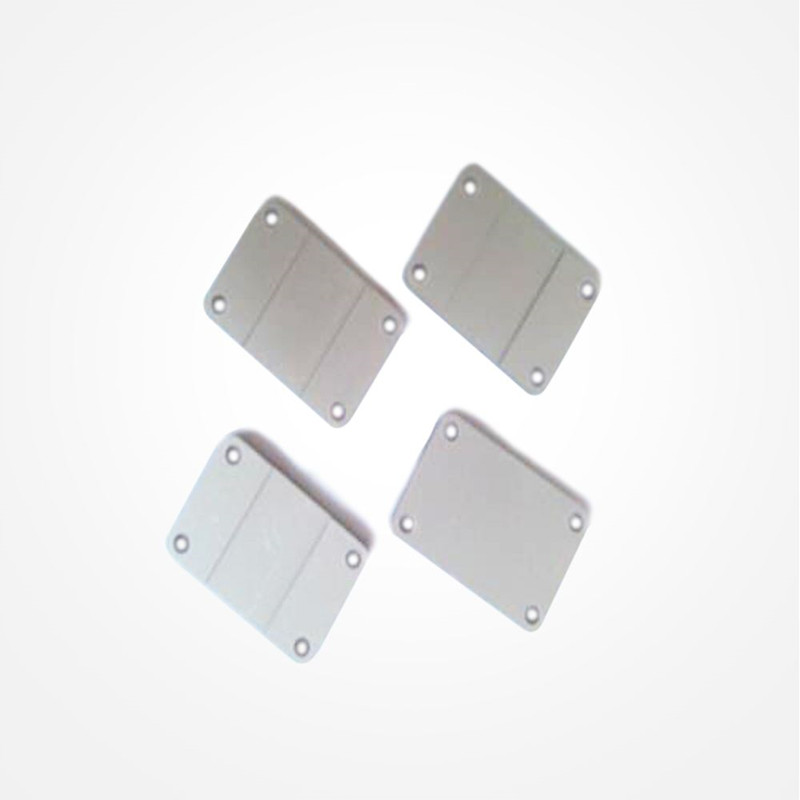

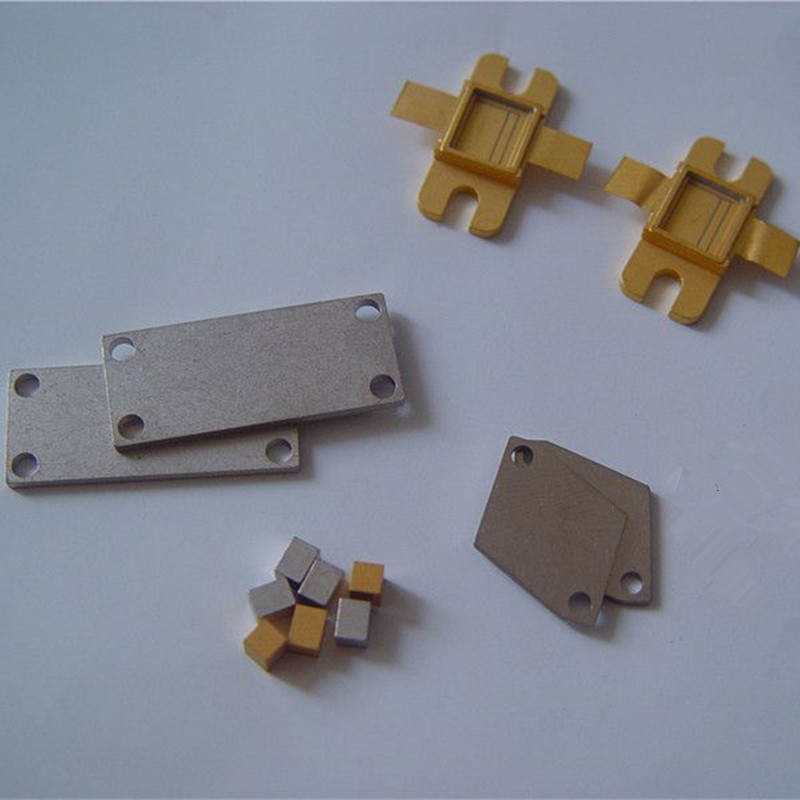

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Discount Price Precision Machining Components - CMC CuMoCu Heat Sink – Fotma , The product will supply to all over the world, such as: Argentina, Senegal, Iraq, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.