Factory directly High Precision Machining - Tungsten Copper WCu Heat Sink – Fotma

Factory directly High Precision Machining - Tungsten Copper WCu Heat Sink – Fotma Detail:

Description

Tungsten copper electronic packaging material has both the low expansion properties of tungsten and the high thermal conductivity properties of copper. What is particularly valuable is that its thermal expansion coefficient and thermal conductivity can be designed by adjusting the composition of the material brought great convenience.

FOTMA uses high-purity and high-quality raw materials, and obtains WCu electronic packaging materials and heat sink materials with excellent performance after pressing, high-temperature sintering and infiltration.

Advantages of Tungsten Copper (WCu) Electronic Packaging Materials

1. The tungsten copper electronic packaging material has an adjustable thermal expansion coefficient, which can be matched with different substrates (such as: stainless steel, valve alloy, silicon, gallium arsenide, gallium nitride, aluminum oxide, etc.);

2. No sintering activation elements are added to maintain good thermal conductivity;

3. Low porosity and good air tightness;

4. Good size control, surface finish and flatness.

5. Provide sheet, formed parts, also can meet the needs of electroplating.

Copper Tungsten Heat Sink Properties

| Material Grade | Tungsten Content Wt% | Density g/cm3 | Thermal Expansion ×10-6 CTE(20℃) | Thermal Conductivity W/(M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCu | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Application of Tungsten Copper Heat Sinks

Materials suitable for packaging with high-power devices, such as substrates, lower electrodes, etc.; high-performance lead frames; thermal control boards and radiators for military and civilian thermal control devices.

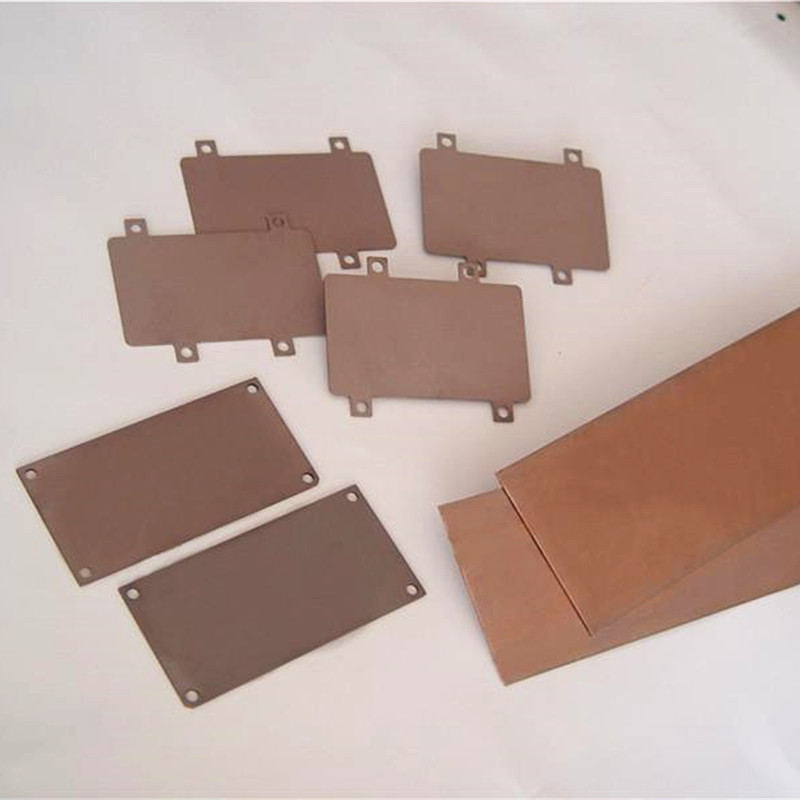

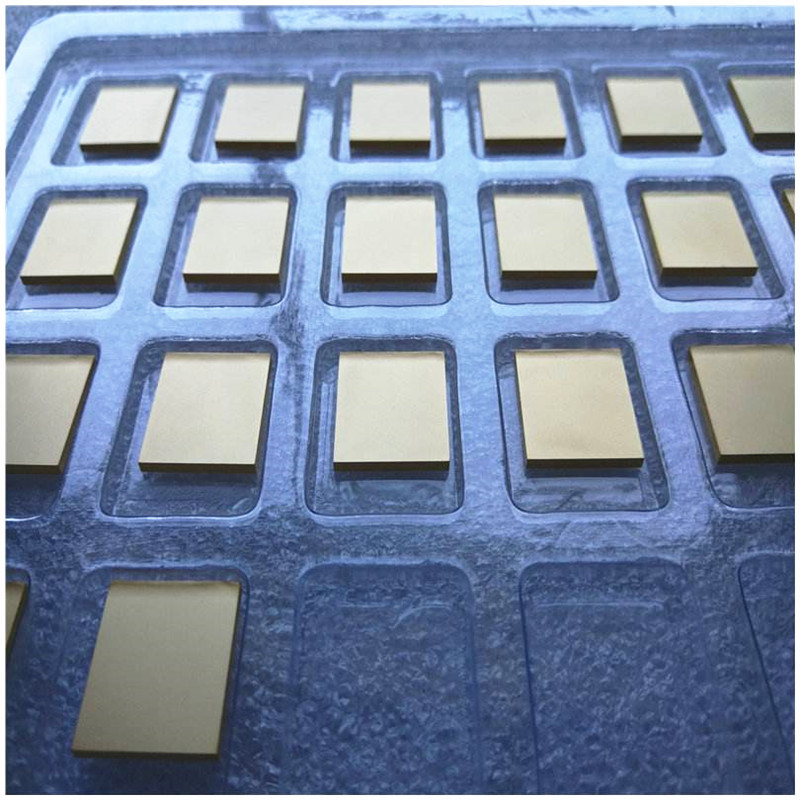

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Factory directly High Precision Machining - Tungsten Copper WCu Heat Sink – Fotma , The product will supply to all over the world, such as: Cannes, Senegal, moldova, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!