Factory directly Solid Carbide Tools - Cemented Tungsten Carbide Tipped Saw Blade – Fotma

Factory directly Solid Carbide Tools - Cemented Tungsten Carbide Tipped Saw Blade – Fotma Detail:

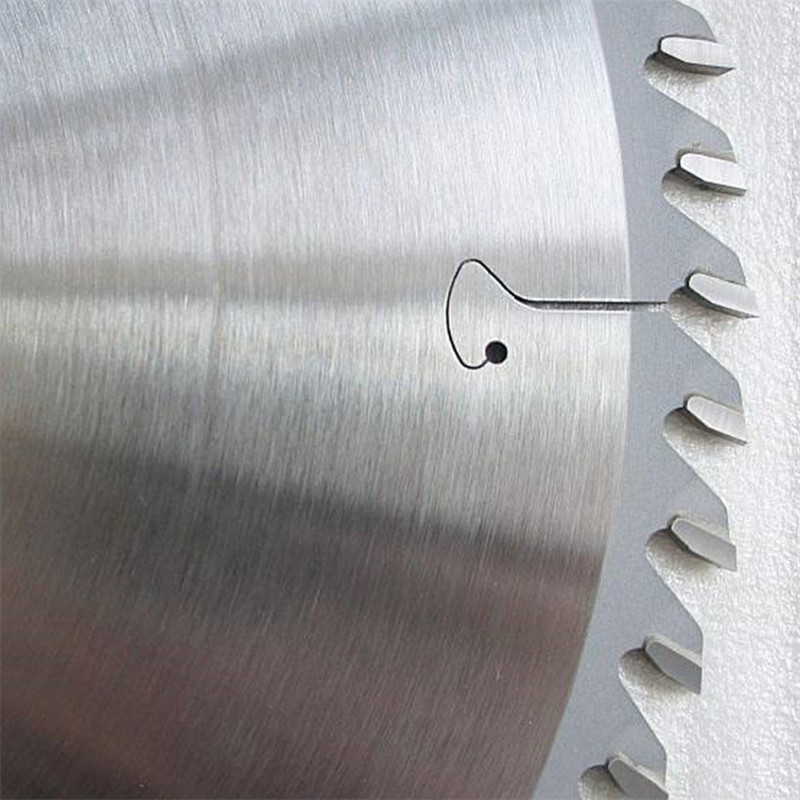

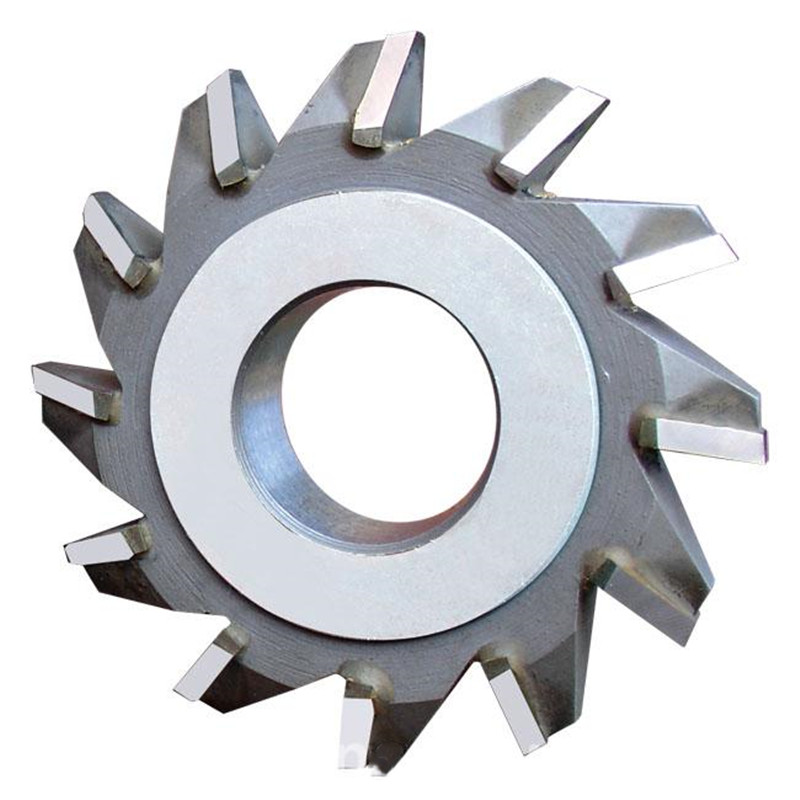

Carbide tipped saw blades are used for cutting wood, metal or other hard materials. They can be manually operated or powered. Our saw blades are used for the surface treatment of cast iron, non-ferrous metals and alloys, as well as for hard metal, carbide rough turning, roughing and precision milling of non-metallic materials.

We can provide improved woodworking carbide grades and custom tooth profile designs upon request, as well as advised on the most suitable saw blade for the customer’s use.

With regard to carbide tungsten carbide saw blades for woodworking circular saw blades, our range of grades covers most applications. The K10 grade has strong performance on both softwood and hardwood. K20 has excellent wear resistance and toughness and is suitable for the processing of wood or pallets as well as the processing of logs. For ferrous metal cutting applications, we also offer alternative grades. Other grades of professional applications are available by special order.

Grade List for Tungsten Carbide Blades

|

Grade |

Density |

Hardness |

Strength |

Applications |

ISO grade |

|

YG6X |

14.8-15 |

91.7-93 |

1600 |

High wear resistance and high strength; |

K10(ANSI C-2) |

|

YT5 |

12.85-13.05 |

89.5-91 |

1700 |

Excellent in strength, impact resistance |

P30(ANSI:C-5) |

|

YT15 |

11.2-11.4 |

92-93 |

1350 |

Good wear resistance, with normal |

P10 |

|

YT14 |

11.3-11.6 |

91.3-92.3 |

1450 |

High in impact resistance and strength; |

P20-P30 |

|

YT535 |

12.6-12.8 |

90-91.5 |

1760 |

High wear resistance and red hardness, |

P30 |

|

ZP25 |

12.5-12.7 |

91.4-92.3 |

1750 |

Fine in wear resistance and toughness; |

P20-P30 |

|

ZP35 |

12.6-12.8 |

90.5-91.5 |

1770 |

A versatile grade, high in red hardness, |

P30-P40 |

|

YG6 |

14.8-15 |

90-92 |

1650 |

Good wear resistance, resistance to |

K15-K20 |

|

YW1 |

13.25-13.5 |

92-93.2 |

1420 |

A versatile grade, good in red hardness, |

M10/P10 |

|

YW2 |

13.15-13.35 |

91.3-92.3 |

1600 |

Good wear resistance and high strength, |

M20/P20-30 |

|

YW2A |

12.85-13.05 |

91.5-92.5 |

1670 |

Good red hardness, able to endure |

M15/P15 |

|

ZM15 |

13.8-14.0 |

91-92.2 |

1720 |

Good Red Hardness, high strength in use, |

M15 |

|

ZM30 |

13.5-13.7 |

90-91.5 |

1890 |

High strength in use, capable of resisting |

M30 |

|

ZK10UF |

14.75-14.95 |

92.6-93.6 |

1690 |

Fine-grained alloy, good wear resistance |

K10-K15 |

|

ZK30UF |

14.3-14.55 |

91.2-92.2 |

2180 |

Fine grain grade. Excellent wear resistance, |

K30 |

|

Note: The specification dates just the standard, the actual specification for the products are much better |

|||||

|

Suggestion: We would like to recommend suitable grade depending on your machining materials. |

|||||

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Factory directly Solid Carbide Tools - Cemented Tungsten Carbide Tipped Saw Blade – Fotma , The product will supply to all over the world, such as: Kazakhstan, Madras, Yemen, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!