Welcome to Fotma Alloy!

Featured

-

Cheap price M6 Titanium Bolts - Pure Titanium Rod Titanium Alloy Bar – Fotma

Description Titanium rod is the raw material used to make titanium alloy and titanium metal. It has the characteristics of low density, high strength and good corrosion resistance. In the aerospace industry, titanium rod is widely used in the manufacture of aircraft structural parts and rocket nozzles; in the chemical industry, it is used as a catalyst carrier and a purification device for electrolytes; in the machinery industry, it can be used as a heat exchanger and condenser material.... -

2022 Latest Design Inconel Bar - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

Fixed Competitive Price Tubular Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma

Description Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace Furnace Heating Element Standard Size for Electric MoSi2 Heater M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24. M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24. MoSi2 Heater Advantages Technical Data of MoSi2 Heating Elements Density Bending Strength Hardness Apparent Po... -

Good User Reputation for Inserts Carbide - Carbide CNC Indexable Inserts – Fotma

Cemented carbide CNC inserts are mainly made of solid carbide as the base body, and are processed through multiple production processes. Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide + cobalt powder after mixing by formula and sintering. It has high hardness, high strength, high wear resistance and high elastic modulus. It belongs to the powder metallurgy industry. . As the teeth of modern industry, carbide cutting tools play a fundamental role in pr... -

Cheapest Price Inconel Wire - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

Top Quality Lathe Machining Parts - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

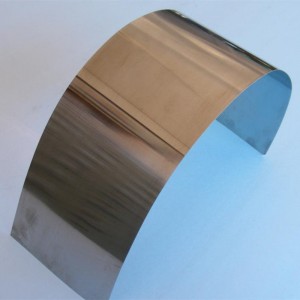

Hot New Products Molybdenum Wire Price - Pure Molybdenum Plate Molybdenum Sheet – Fotma

Specifications Molybdenum Content: 99.95%. Surface: Black surface, chemical washed clean surface, rolled surface, ground surface. Density: no less than 10.1 g/cm3. Standard: GB4188-84. Grade: MO-1, MO-2. Thickness < 0.15 mm Max size 150 x 1000 mm Thickness 0.20 mm Max size 500 x 1500 mm Thickness 0.25 – 0.4 mm Max size 610 x 3000 mm Thickness 0.5 – 2.0 mm Max size 610 x 1500 mm Thickness 2.5 – 3.5 mm Max size 500 x 1000 mm Molybdenum sheet is... -

2022 wholesale price Carbide Cutter Price - Carbide CNC Indexable Inserts – Fotma

Cemented carbide CNC inserts are mainly made of solid carbide as the base body, and are processed through multiple production processes. Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide + cobalt powder after mixing by formula and sintering. It has high hardness, high strength, high wear resistance and high elastic modulus. It belongs to the powder metallurgy industry. . As the teeth of modern industry, carbide cutting tools play a fundamental role in pr... -

Discountable price Precision Machining Companies - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

High Performance 5 Axis Cnc Parts - Heavy Duty Forged Steel Shaft – Fotma

Type of Steel Shafts Forging Shaft, Forging Gear Shaft, Forging Shaft For Power Generator, Forging Shaft For Steam Turbine and Hydraulic Turbine, Forging Shaft for Wind Turbine, Forging Shaft For Ship, Forging Shaft For Ship Turbocharger, Forging Shaft For Fan(Blower),Forging Shaft For Metallurgical $ Mining, Stainless Steel Forging Shaft and Other Forging Shaft. Forged Steel Shaft Application Forged steel shafts are mainly used in various machinery equipment in the fields of mining... -

factory customized Small Tungsten Cubes - Pure Tungsten Rod Tungsten Bar – Fotma

Purity 99.95% Tungsten Rods Tungsten Bars Brief Introduction 1. Standard: ASTM B760/ GB T3875. 2. Material Grade: W1. 3. Tungsten content: 99.95%. 4. Density: No less than 19.1g/cm3. 5. Size: 5.0mm~100mm diameter, Length: 50-1000mm. 6. Surface: Black, chemical cleaned or machined/ground. 7. Production capacity: 1000kg/month. 8. Applications of pure tungsten rod / tungsten bar: Pure tungsten rod/tungsten bar are generally used to manufacture emitting cathode, high temperature settin... -

New Arrival China Cnc Printing - Heavy Duty Forged Steel Shaft – Fotma

Type of Steel Shafts Forging Shaft, Forging Gear Shaft, Forging Shaft For Power Generator, Forging Shaft For Steam Turbine and Hydraulic Turbine, Forging Shaft for Wind Turbine, Forging Shaft For Ship, Forging Shaft For Ship Turbocharger, Forging Shaft For Fan(Blower),Forging Shaft For Metallurgical $ Mining, Stainless Steel Forging Shaft and Other Forging Shaft. Forged Steel Shaft Application Forged steel shafts are mainly used in various machinery equipment in the fields of mining...