Welcome to Fotma Alloy!

Featured

-

Reliable Supplier Precision Machining Parts - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

Factory Free sample Inconel Tubing - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

China Gold Supplier for Proto Type Machining - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

OEM Manufacturer Titanium Copper Alloy - Pure Titanium Plate Titanium Alloy Sheet – Fotma

Description Pure Titanium Plate / Titanium Alloy Sheet Specifications: Material Grade: Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr6, Gr9, Gr11, Gr12, Gr16, Gr17, Gr25, TA0,TA1,TA2,TA5,TA6,TA7,TA9,TA10,TB2,TC1,TC2,TC3,TC4 Standard ASTM B265, ASME SB265, DIN17851, TiA16Zr5Mo1.5, JIS4100-2007, GB3461-2007 Size: Cold rolled: Thick 0.02mm ~ 5mm * Wide 1500mm max * Long 2500mm max Hot rolled: Thick 5mm ~ 100mm * Wide 3000mm max * Long 6000mm max Titanium Alloy Plate Application 1. Based on High... -

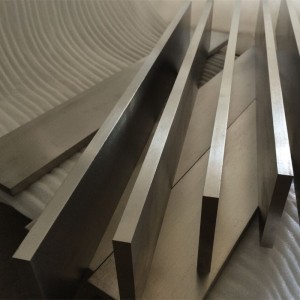

Factory selling Tungsten Carbide Button - Cemented Tungsten Carbide Cutting Blade – Fotma

Description Cemented tungsten carbide cutting blade is widely used for slitting paper, plastic films, cloth, foam, rubber, copper foils, aluminum foils, graphite, etc. All of carbide blades can be manufactured as per customers’ requests. Ground by professional equipment, our carbide blades are supplied with nice appearance, high precision, durable life, which makes its high cost performance. Specifications of FOTMA Cemented Carbide Blades Material: Tungsten Carbide. Advantage:... -

Renewable Design for Precision Machining - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

Factory directly Solid Carbide Tools - Cemented Carbide Mechanical Sealing Rings – Fotma

Cemented carbide sealing ring is made of tungsten carbide powder as raw material, adding an appropriate amount of cobalt powder or nickel powder as a binder, pressed into a ring shape through a certain mold, and sintered in a vacuum furnace or hydrogen reduction furnace. It is a relatively common production and processing product. Because of its high hardness, good anti-corrosion performance, and strong sealing, it has many applications in petrochemical and other sealing industries. Carbide s... -

Manufactur standard Buy Tungsten Carbide - Carbide CNC Indexable Inserts – Fotma

Cemented carbide CNC inserts are mainly made of solid carbide as the base body, and are processed through multiple production processes. Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide + cobalt powder after mixing by formula and sintering. It has high hardness, high strength, high wear resistance and high elastic modulus. It belongs to the powder metallurgy industry. . As the teeth of modern industry, carbide cutting tools play a fundamental role in pr... -

professional factory for W Alloy - Zirconia Ceramic Products – Fotma

Description Zirconia ceramics, ZrO2 ceramics, Zirconia Ceramic have excellent properties such as high melting point and boiling point, high hardness, insulator at room temperature, and electrical conductivity at high temperature. Applications of Zirconia Ceramics Zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coeffici... -

Manufacturer of Uns N10276 Material - Tungsten Copper WCu Heat Sink – Fotma

Description Tungsten copper electronic packaging material has both the low expansion properties of tungsten and the high thermal conductivity properties of copper. What is particularly valuable is that its thermal expansion coefficient and thermal conductivity can be designed by adjusting the composition of the material brought great convenience. FOTMA uses high-purity and high-quality raw materials, and obtains WCu electronic packaging materials and heat sink materials with excellent pe... -

Leading Manufacturer for Precision Cnc Machined Components - Heavy Duty Forged Steel Shaft – Fotma

Type of Steel Shafts Forging Shaft, Forging Gear Shaft, Forging Shaft For Power Generator, Forging Shaft For Steam Turbine and Hydraulic Turbine, Forging Shaft for Wind Turbine, Forging Shaft For Ship, Forging Shaft For Ship Turbocharger, Forging Shaft For Fan(Blower),Forging Shaft For Metallurgical $ Mining, Stainless Steel Forging Shaft and Other Forging Shaft. Forged Steel Shaft Application Forged steel shafts are mainly used in various machinery equipment in the fields of mining... -

China Manufacturer for Machining Components - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding...