Welcome to Fotma Alloy!

Featured

-

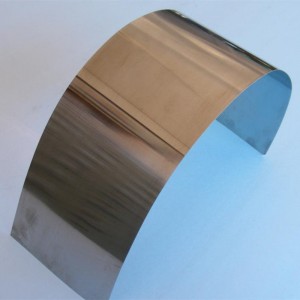

Low price for Pure Molybdenum - Pure Molybdenum Plate Molybdenum Sheet – Fotma

Specifications Molybdenum Content: 99.95%. Surface: Black surface, chemical washed clean surface, rolled surface, ground surface. Density: no less than 10.1 g/cm3. Standard: GB4188-84. Grade: MO-1, MO-2. Thickness < 0.15 mm Max size 150 x 1000 mm Thickness 0.20 mm Max size 500 x 1500 mm Thickness 0.25 – 0.4 mm Max size 610 x 3000 mm Thickness 0.5 – 2.0 mm Max size 610 x 1500 mm Thickness 2.5 – 3.5 mm Max size 500 x 1000 mm Molybdenum sheet is... -

Reasonable price Molybdenum Foil - 99.95% Pure Molybdenum Rod Molybdenum Bar – Fotma

Specifications Molybdenum content: 99.95%. Diameter: 1.0mm – 100mm. Length: 20-2000mm. Surface: Forged surface, Machined surface, Find ground surface. Density: ≥ 10.1 g/cm3. Standard: GB4188-84. Type: MO-1, MO-2. Polished Molybdenum rods are applied for making components in Electronic vacuum devices, guide rod, electrode, lead, etc. Mo-1 Purity: 99.95% Min. Mo. Rod are applied for making high temperature-resistance devices, heater rod in furnace. Molybdenum Rods Application 1) ... -

Trending Products 625 Nickel - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

Manufacturer for Soft Magnetic Alloy - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

Factory source Nickel Tube - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

Quality Inspection for Cuni Alloy - Zirconia Ceramic Products – Fotma

Description Zirconia ceramics, ZrO2 ceramics, Zirconia Ceramic have excellent properties such as high melting point and boiling point, high hardness, insulator at room temperature, and electrical conductivity at high temperature. Applications of Zirconia Ceramics Zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coeffici... -

Special Design for Titanium Filler Wire - Pure Titanium Rod Titanium Alloy Bar – Fotma

Description Titanium rod is the raw material used to make titanium alloy and titanium metal. It has the characteristics of low density, high strength and good corrosion resistance. In the aerospace industry, titanium rod is widely used in the manufacture of aircraft structural parts and rocket nozzles; in the chemical industry, it is used as a catalyst carrier and a purification device for electrolytes; in the machinery industry, it can be used as a heat exchanger and condenser material.... -

Reliable Supplier Carbide Tip Tools - Cemented Tungsten Carbide Spray Nozzles – Fotma

Applications of Cemented Carbide Nozzles: Carbide nozzles are widely used in surface treatment, sandblasting, painting, electronics, chemical process and other industries. Carbide nozzles are also used in different applications such as for wire straightening, wire guides and others. Carbide for sandblasting Carbide nozzles are an essential part of sandblasting equipment. The sandblasting equipment is powered by compressed air, and sprays the material to the surface of the workpiece at a high ... -

8 Year Exporter 617 Inconel - Boron Nitride Ceramic Products – Fotma

Introduction of boron nitride ceramic products This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different ... -

Factory wholesale Titanium Aluminum Carbide - Cemented Tungsten Carbide Cutting Blade – Fotma

Description Cemented tungsten carbide cutting blade is widely used for slitting paper, plastic films, cloth, foam, rubber, copper foils, aluminum foils, graphite, etc. All of carbide blades can be manufactured as per customers’ requests. Ground by professional equipment, our carbide blades are supplied with nice appearance, high precision, durable life, which makes its high cost performance. Specifications of FOTMA Cemented Carbide Blades Material: Tungsten Carbide. Advantage:... -

Big discounting Carbide Cutting Inserts - Cemented Tungsten Carbide Button Bits – Fotma

Description Tungsten carbide button has superior wear resistance and impact toughness, and similar products with higher speed of drilling and digging. Series of ball tooth bit passivation using cycle is long, not to grind the life span of about the same diameter RenPian grinding head drill bit 5-6 times of life, is beneficial to save auxiliary working hours, physical labor and reduce workers to speed up the project. Our Carbide Products Advantages 1. Promise the 100% virgin material... -

High Performance Cemented Carbide - Carbide CNC Indexable Inserts – Fotma

Cemented carbide CNC inserts are mainly made of solid carbide as the base body, and are processed through multiple production processes. Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide + cobalt powder after mixing by formula and sintering. It has high hardness, high strength, high wear resistance and high elastic modulus. It belongs to the powder metallurgy industry. . As the teeth of modern industry, carbide cutting tools play a fundamental role in pr...