Welcome to Fotma Alloy!

Featured

-

One of Hottest for Titanium Gold Sheet - Pure Titanium Plate Titanium Alloy Sheet – Fotma

Description Pure Titanium Plate / Titanium Alloy Sheet Specifications: Material Grade: Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr6, Gr9, Gr11, Gr12, Gr16, Gr17, Gr25, TA0,TA1,TA2,TA5,TA6,TA7,TA9,TA10,TB2,TC1,TC2,TC3,TC4 Standard ASTM B265, ASME SB265, DIN17851, TiA16Zr5Mo1.5, JIS4100-2007, GB3461-2007 Size: Cold rolled: Thick 0.02mm ~ 5mm * Wide 1500mm max * Long 2500mm max Hot rolled: Thick 5mm ~ 100mm * Wide 3000mm max * Long 6000mm max Titanium Alloy Plate Application 1. Based on High... -

Super Purchasing for Alloy 600 - Zirconia Ceramic Products – Fotma

Description Zirconia ceramics, ZrO2 ceramics, Zirconia Ceramic have excellent properties such as high melting point and boiling point, high hardness, insulator at room temperature, and electrical conductivity at high temperature. Applications of Zirconia Ceramics Zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coeffici... -

Factory Cheap Hot Tantalum Rod - Tantalum Rod Tantalum Alloy Bar – Fotma

Applications of Tantalum Rods Tantalum Alloy Bar Tantalum rods can be used to make heating parts and heat insulation parts for vacuum blast furnaces, in the chemical industry, it can be used to make digesters, heaters, coolers, various utensils, etc., as well as in the fields of aviation, aerospace industry, medical equipment, etc have a wide range of applications. Tantalum rod Tantalum Alloy Bar Specification Material Grade: R05200, R05400. Standard: ASTM B365. Tantalum Purity: ≥99... -

18 Years Factory Aluminum Cnc Machining Service - Forged Steel Girth Gear – Fotma

Customized Forged Steel Girth Gear Ring/Gear Segment Girth gear is the key component to support the transmission system stability of rotary kiln and ball mill, which are often forged or cast structure high quality and strength alloy steel with surface carburizing or hardening treatment. Girth gears have the high bearing capacity and durable. In practical application, which is widely used in high speed and heavy load machinery, because of its stable transmission, low impact, vibration and... -

Factory selling Aluminum Cnc Machining - Heavy Duty Forged Steel Shaft – Fotma

Type of Steel Shafts Forging Shaft, Forging Gear Shaft, Forging Shaft For Power Generator, Forging Shaft For Steam Turbine and Hydraulic Turbine, Forging Shaft for Wind Turbine, Forging Shaft For Ship, Forging Shaft For Ship Turbocharger, Forging Shaft For Fan(Blower),Forging Shaft For Metallurgical $ Mining, Stainless Steel Forging Shaft and Other Forging Shaft. Forged Steel Shaft Application Forged steel shafts are mainly used in various machinery equipment in the fields of mining... -

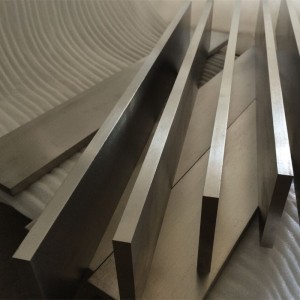

Reliable Supplier Sintered Tungsten - Pure Tungsten Plate Tungsten Sheet – Fotma

Purity 99.95% Tungsten Plates Tungsten Sheets Brief Introduction 1. Material Grade: W1. 2. Tungsten purity: 99.95%. 3. Density: no less than 19.1g/cm3. 4. Size: 0.1mm~100mm thickness x 50-600mm width x 50-1000mm length. 5. Surface: Black, chemical cleaned or machined/ground. 6. Tungsten Sheets Feature: High melting point, High-density, high temperature oxidation resistance, long service life, resistance to corrosion, High quality, workability. 7. Applications of pure tungsten plate ... -

Cemented Tungsten Carbide Spray Nozzles – Fotma

Applications of Cemented Carbide Nozzles: Carbide nozzles are widely used in surface treatment, sandblasting, painting, electronics, chemical process and other industries. Carbide nozzles are also used in different applications such as for wire straightening, wire guides and others. Carbide for sandblasting Carbide nozzles are an essential part of sandblasting equipment. The sandblasting equipment is powered by compressed air, and sprays the material to the surface of the workpiece at a high ... -

Factory Cheap Evaporation Materials - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

Wholesale Discount Tzm Material - CMC CuMoCu Heat Sink – Fotma

CMC CuMoCu Material Application Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc. Heat sink material on aircraft, heat sink material on radar. CMC Heat Sink Advantages 1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding... -

PriceList for Tungsten Rod For Sale - Pure Tungsten Rod Tungsten Bar – Fotma

Purity 99.95% Tungsten Rods Tungsten Bars Brief Introduction 1. Standard: ASTM B760/ GB T3875. 2. Material Grade: W1. 3. Tungsten content: 99.95%. 4. Density: No less than 19.1g/cm3. 5. Size: 5.0mm~100mm diameter, Length: 50-1000mm. 6. Surface: Black, chemical cleaned or machined/ground. 7. Production capacity: 1000kg/month. 8. Applications of pure tungsten rod / tungsten bar: Pure tungsten rod/tungsten bar are generally used to manufacture emitting cathode, high temperature settin... -

Hot sale Factory Cnc Machining 3d Printing - Forged Steel Girth Gear – Fotma

Customized Forged Steel Girth Gear Ring/Gear Segment Girth gear is the key component to support the transmission system stability of rotary kiln and ball mill, which are often forged or cast structure high quality and strength alloy steel with surface carburizing or hardening treatment. Girth gears have the high bearing capacity and durable. In practical application, which is widely used in high speed and heavy load machinery, because of its stable transmission, low impact, vibration and... -

OEM/ODM Supplier W Bar - Zirconia Ceramic Products – Fotma

Description Zirconia ceramics, ZrO2 ceramics, Zirconia Ceramic have excellent properties such as high melting point and boiling point, high hardness, insulator at room temperature, and electrical conductivity at high temperature. Applications of Zirconia Ceramics Zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coeffici...