Welcome to Fotma Alloy!

Fixed Competitive Price Tubular Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma

Fixed Competitive Price Tubular Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma Detail:

Description

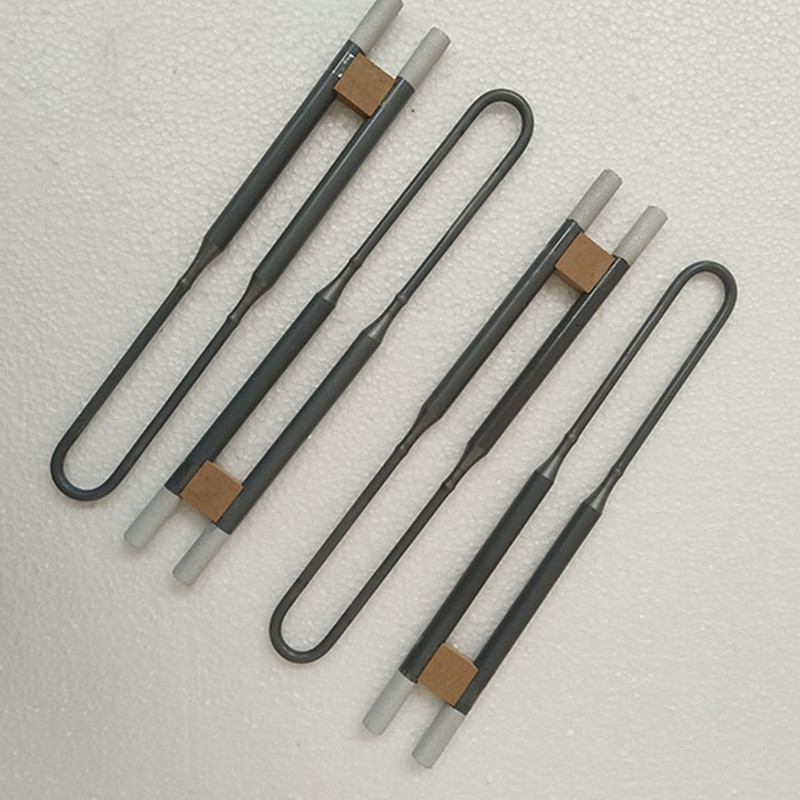

Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace

Furnace Heating Element

Standard Size for Electric MoSi2 Heater

M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

MoSi2 Heater Advantages

Technical Data of MoSi2 Heating Elements

| Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

| 5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

The Influence of Operation Temperature on the Heater Surface in Different Atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700 | 1800 |

| N2 | 1600 | 1700 |

| He | 1600 | 1700 |

| -80°C Dry H2 | 1150 | 1150 |

| -20°C Wet H2 | 1450 | 1450 |

| 10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

Product detail pictures:

Related Product Guide:

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for Fixed Competitive Price Tubular Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma , The product will supply to all over the world, such as: Los Angeles, Sweden, United Arab Emirates, We always hold on the company's principle "honest, professional, effective and innovation", and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We are determined to become the integrator of our product market and one-stop service provider of our product market.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

Write your message here and send it to us