Welcome to Fotma Alloy!

High Quality for Molybdenum Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma

High Quality for Molybdenum Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma Detail:

Description

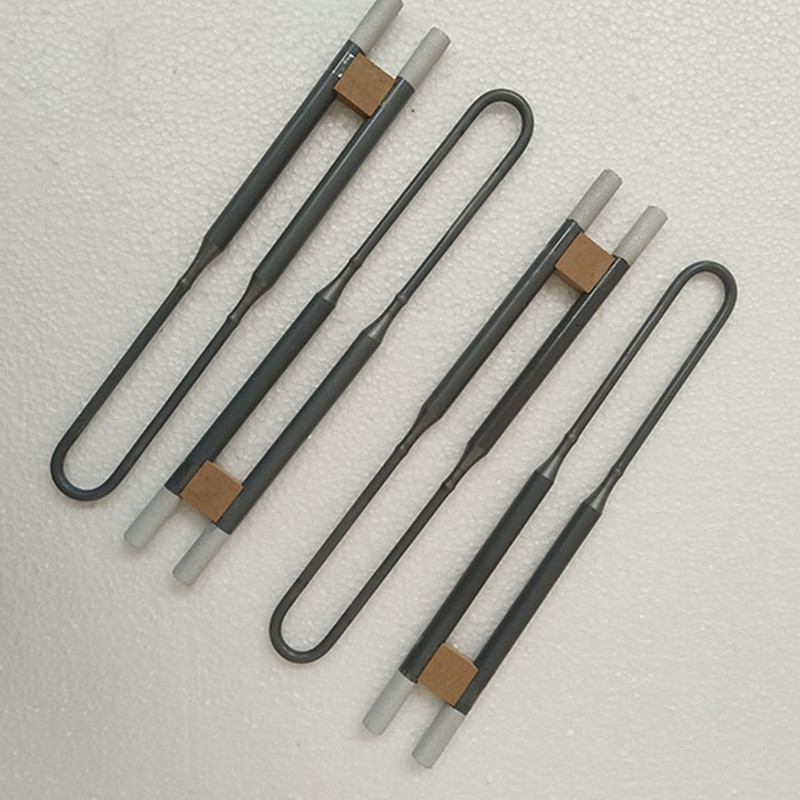

Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace

Furnace Heating Element

Standard Size for Electric MoSi2 Heater

M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

MoSi2 Heater Advantages

Technical Data of MoSi2 Heating Elements

| Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

| 5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

The Influence of Operation Temperature on the Heater Surface in Different Atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700 | 1800 |

| N2 | 1600 | 1700 |

| He | 1600 | 1700 |

| -80°C Dry H2 | 1150 | 1150 |

| -20°C Wet H2 | 1450 | 1450 |

| 10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for High Quality for Molybdenum Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma , The product will supply to all over the world, such as: South Africa, Kuwait, San Francisco, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

Write your message here and send it to us