Low MOQ for Carbide Cutting Tool - Carbide CNC Indexable Inserts – Fotma

Low MOQ for Carbide Cutting Tool - Carbide CNC Indexable Inserts – Fotma Detail:

Cemented carbide CNC inserts are mainly made of solid carbide as the base body, and are processed through multiple production processes.

Cemented carbide, also known as tungsten steel, is made of high-quality tungsten carbide + cobalt powder after mixing by formula and sintering. It has high hardness, high strength, high wear resistance and high elastic modulus. It belongs to the powder metallurgy industry. . As the teeth of modern industry, carbide cutting tools play a fundamental role in promoting the development of the manufacturing industry.

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remain basically unchanged even at a temperature of 500 °C , still has high hardness at 1000℃.

Application:

Carbide Inserts are widely used for cutting, milling, turning, woodworking, grooving etc.

Made by high quality virgin tungsten carbide raw materials. Good quality surface treating and TiN coating.

Our company has in its possession an advanced production line for manufacturing dies and moulds and a production line for post machined cemented carbide products. We can also supply tailor-made products of various specifications based on the requirements of our customers.

Cemented Carbide Grades for CNC Indexable Inserts.

|

Grade |

Applications |

|

C2 Uncoated |

High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast iron. |

|

C5 Uncoated |

Excellent in strength, impact resistance and resistance to thermal shock ; Rough turning, rough planing and semi planing of Carbon steel and alloy steel. |

|

ZK10UF |

Fine-grained alloy, good wear resistance and high strength. Semi-finishing and finishing of cast iron and nonferrous metals. It is the unique material for making of solid carbide tools for holing. |

|

ZK30UF |

Fine grain grade. Excellent wear resistance, high in strength and impact resistance. Machining of cast irons, nonferrous metals and non-metallic materials. It is the unique material of solid carbide tools for holing. |

|

ZP25 |

Fine in wear resistance and toughness; Rough turning, milling, planing and depth drilling of carbon steel, cast steel, manganese steel and alloy steel. |

|

ZP35 |

A versatile grade, high in red hardness, strength and resistance to impact and thermal shocking. Roughing and strong cutting of steel and cast steel. |

|

Suggestion: We would like to recommend suitable grade depending on your machining materials. |

|

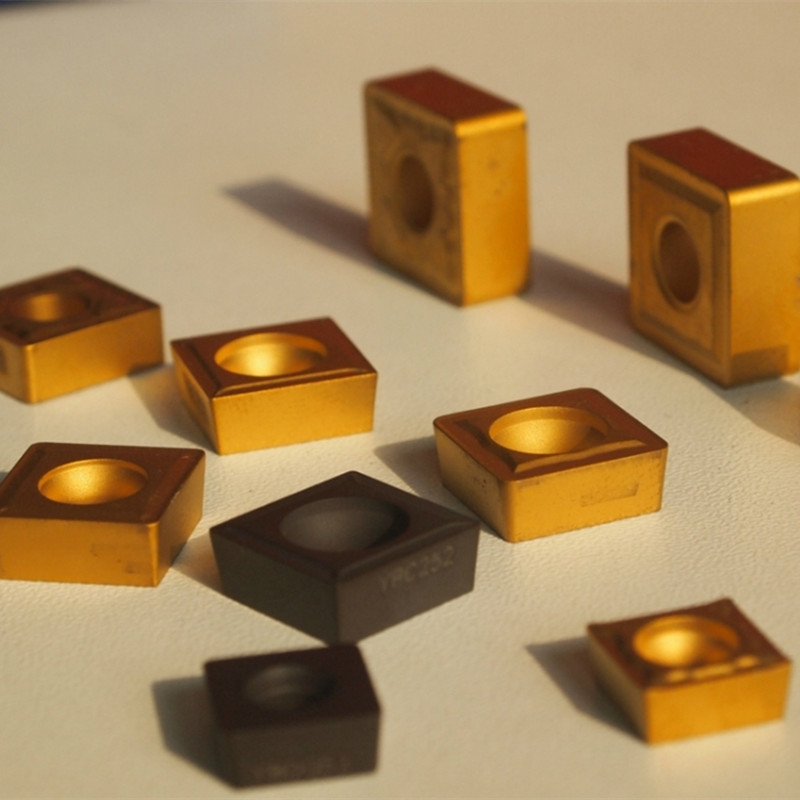

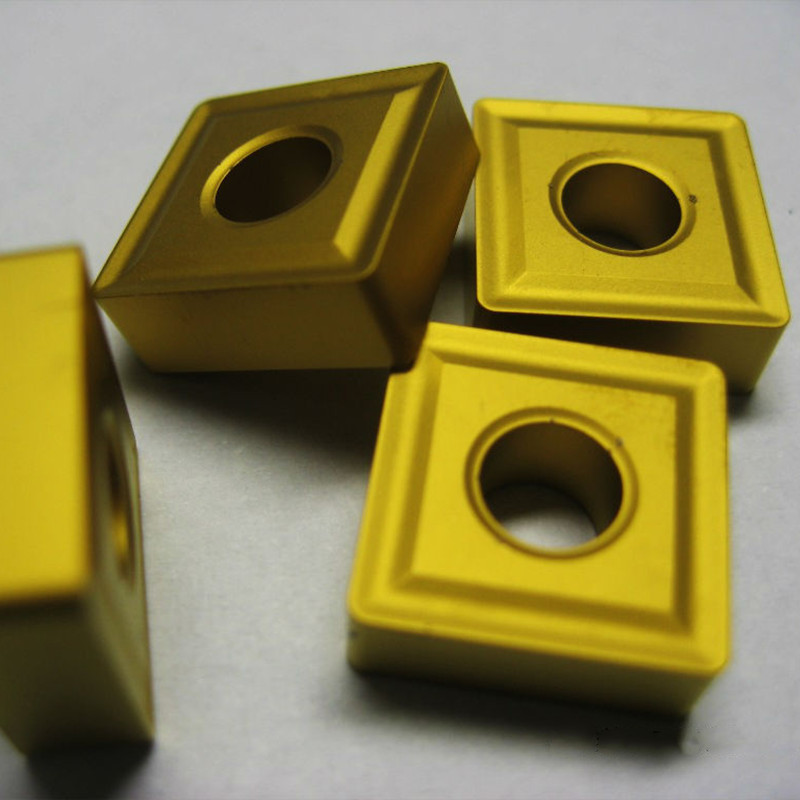

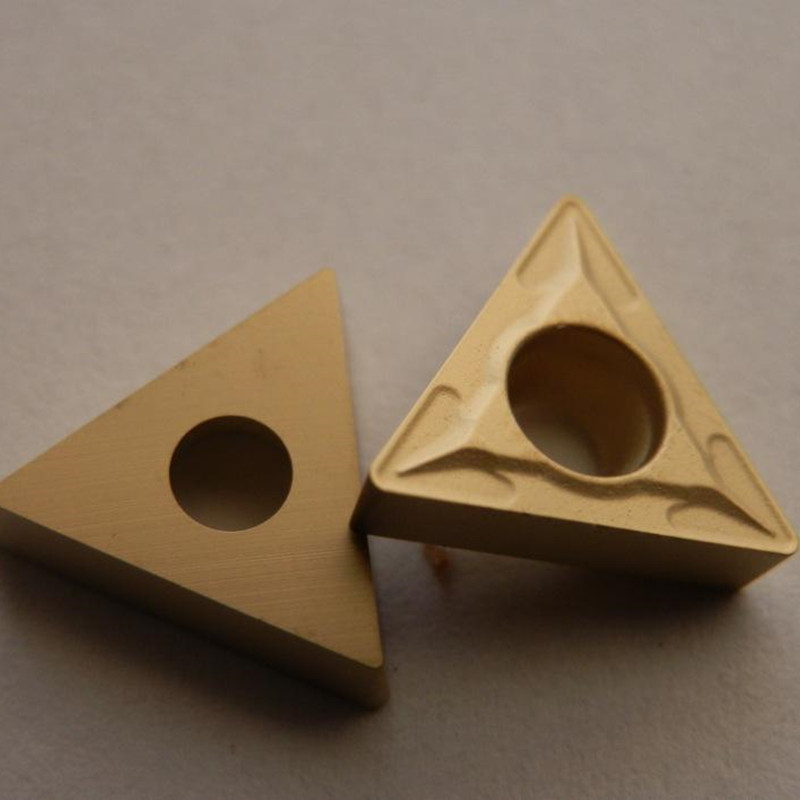

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for Low MOQ for Carbide Cutting Tool - Carbide CNC Indexable Inserts – Fotma , The product will supply to all over the world, such as: Guatemala, Melbourne, Ecuador, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.