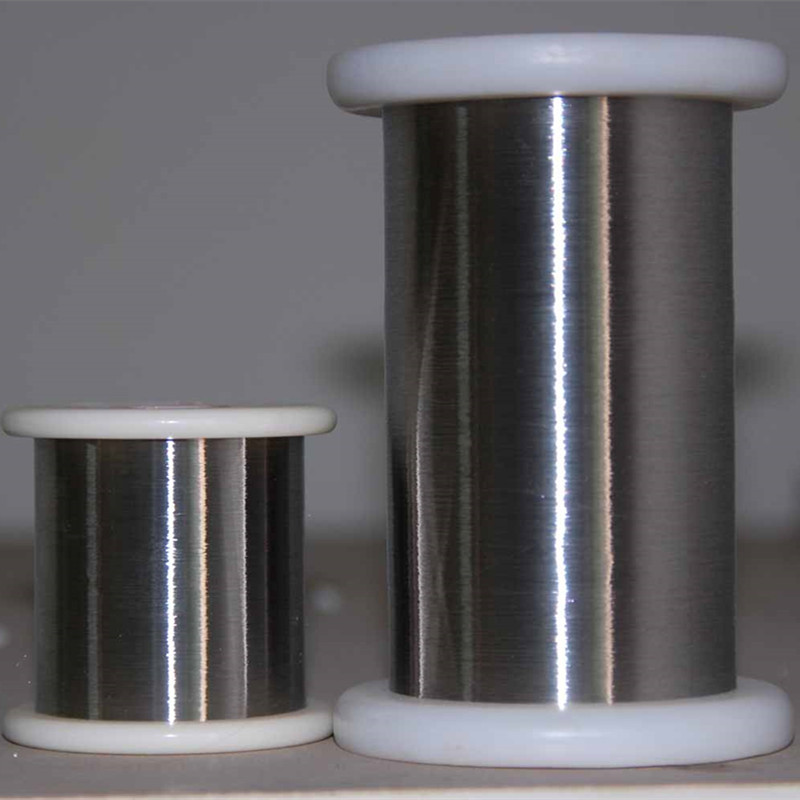

Nickel Chromium NiCr Alloy Wire

0.03mm Wire NiCr Alloy, 637 MPA Nickel Chromium Heating Wire, Ni90Cr10 NiCr Alloy

Ni90Cr10 is an austenitic nickel-chromium alloy suitable for temperature applications up to 1250°C. High chromium content (30% in average) provides very good life time, especially in the furnace applications, it is most used in vape, as a heating element.

Ni90Cr10 is characterized by high resistivity, good oxidation resistance, good ductility after use and excellent weldability. Alloy is not subject to “green rot” and is particularly well suited for reducing and oxidizing atmospheres.

Ni70Cr30 is used for electric heating elements in industrial furnaces. Typical applications are: electric and enamelling furnaces, storage heaters, furnaces and kilns with a changing atmospheres.

Applications of NiCr Alloy Wires:

Nickel-chromium materials have high high temperature strength and strong plasticity.

Widely used in industrial electric furnaces, household appliances, far-infrared devices.

Nickel-chromium and iron, aluminum, silicon, carbon, sulfur and other elements can be made into alloy nickel-chromium wire with high resistivity and heat resistance. It is the electric heating element of electric stove, electric soldering iron, electric iron, etc.

Advantages of Nickel-Chromium Wire:

The resistance is relatively high, the surface layer has good oxidation resistance, and the compressive strength is maintained better than that of iron-chromium-aluminum wire under high temperature natural environment, and high temperature operation is not easy to produce deformation. Nickel-chromium wire has good plastic deformation, very good processing characteristics and forge-ability, easy to produce and process, easy to repair and difficult to change in structure. In addition, nickel-chromium wire has high emissivity, good corrosion resistance and long application period.

Nickel-chromium alloy performance tables

|

Performance material |

Cr10Ni90 |

Cr20Ni80 |

Cr30Ni70 |

Cr15Ni60 |

Cr20Ni35 |

Cr20Ni30 |

|

|

Composition |

Ni |

90 |

Rest |

Rest |

55.0~61.0 |

34.0~37.0 |

30.0~34.0 |

|

Cr |

10 |

20.0~23.0 |

28.0~31.0 |

15.0~18.0 |

18.0~21.0 |

18.0~21.0 |

|

|

Fe |

|

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|

|

Maximum temperature℃ |

1300 |

1200 |

1250 |

1150 |

1100 |

1100 |

|

|

Meltiing point ℃ |

1400 |

1400 |

1380 |

1390 |

1390 |

1390 |

|

|

Density g/cm3 |

8.7 |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|

|

Resistivity |

|

1.09±0.05 |

1.18±0.05 |

1.12±0.05 |

1.00±0.05 |

1.04±0.05 |

|

|

μΩ·m,20℃ |

|||||||

|

Elongation at rupture |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Specific heat |

|

0.44 |

0.461 |

0.494 |

0.5 |

0.5 |

|

|

J/g.℃ |

|||||||

|

Thermal conductivity |

|

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|

|

KJ/m.h℃ |

|||||||

|

Coefficient of lines expansion |

|

18 |

17 |

17 |

19 |

19 |

|

|

a×10-6/ |

|||||||

|

(20~1000℃) |

|||||||

|

Micrographic structure |

|

Austenite |

Austenite |

Austenite |

Austenite |

Austenite |

|

|

Magnetic properties |

|

Nonmagnetic |

Nonmagnetic |

Nonmagnetic |

Weak magnetic |

Weak magnetic |

|