Welcome to Fotma Alloy!

OEM manufacturer Electric Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma

OEM manufacturer Electric Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma Detail:

Description

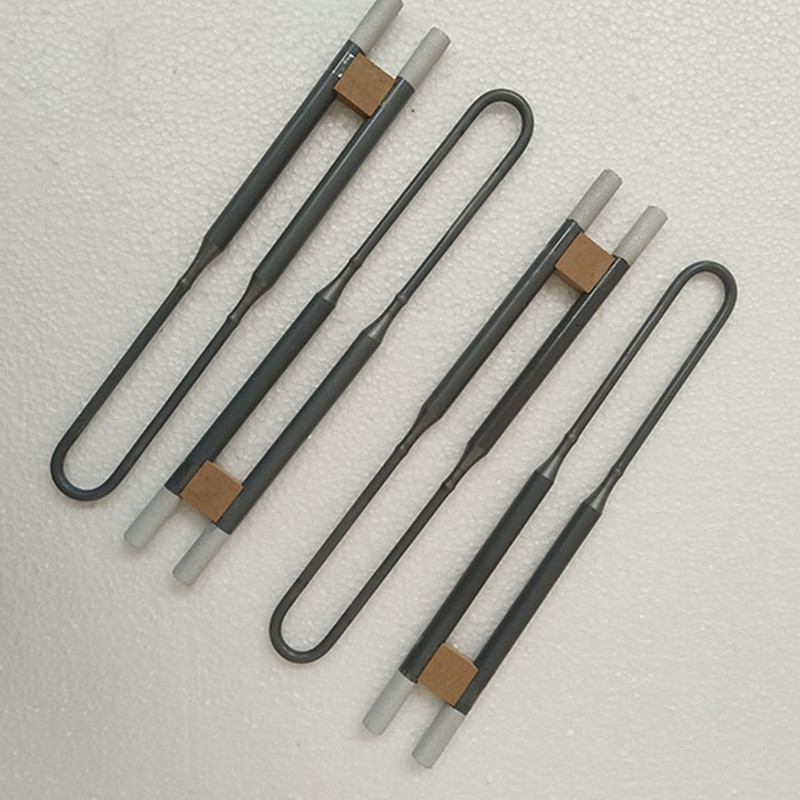

Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace

Furnace Heating Element

Standard Size for Electric MoSi2 Heater

M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

MoSi2 Heater Advantages

Technical Data of MoSi2 Heating Elements

| Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

| 5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

The Influence of Operation Temperature on the Heater Surface in Different Atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700 | 1800 |

| N2 | 1600 | 1700 |

| He | 1600 | 1700 |

| -80°C Dry H2 | 1150 | 1150 |

| -20°C Wet H2 | 1450 | 1450 |

| 10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for OEM manufacturer Electric Heating Elements - Silicon Molybdenum MoSi2 Heating Elements – Fotma , The product will supply to all over the world, such as: Guyana, Saudi Arabia, Latvia, Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Write your message here and send it to us