Online Exporter Incoloy Material - CMC CuMoCu Heat Sink – Fotma

Online Exporter Incoloy Material - CMC CuMoCu Heat Sink – Fotma Detail:

CMC CuMoCu Material Application

Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc.

Heat sink material on aircraft, heat sink material on radar.

CMC Heat Sink Advantages

1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding strength between molybdenum and copper is excellent, So that the finished material has the lowest thermal expansion coefficient and the best thermal conductivity;

2. The molybdenum-copper ratio of CMC is very good, and the deviation of each layer is controlled within 10%; SCMC material is a multi-layer composite material. The structural composition of the material from top to bottom is: copper sheet – molybdenum sheet – copper sheet – molybdenum sheet… copper sheet, it can be composed of 5 layers, 7 layers or even more layers. Compared with CMC, SCMC will have the lowest thermal expansion coefficient and the highest thermal conductivity.

Grade of CMC Cu-Mo-Cu Materials

| Grade | Density g/cm3 | Coefficient of thermal Expansion ×10-6 (20℃) | Thermal conductivity W/(M·K) |

| CMC111 | 9.32 | 8.8 | 305(XY)/250(Z) |

| CMC121 | 9.54 | 7.8 | 260(XY)/210(Z) |

| CMC131 | 9.66 | 6.8 | 244(XY)/190(Z) |

| CMC141 | 9.75 | 6 | 220(XY)/180(Z) |

| CMC13/74/13 | 9.88 | 5.6 | 200(XY)/170(Z) |

| Material | Wt% Molybdenum Content | g/cm3 Density | Thermal conductivity at 25℃ | Coefficient of thermal Expansion at 25℃ |

| S-CMC | 5 | 9.0 | 362 | 14.8 |

| 10 | 9.0 | 335 | 11.8 | |

| 13.3 | 9.1 | 320 | 10.9 | |

| 20 | 9.2 | 291 | 7.4 |

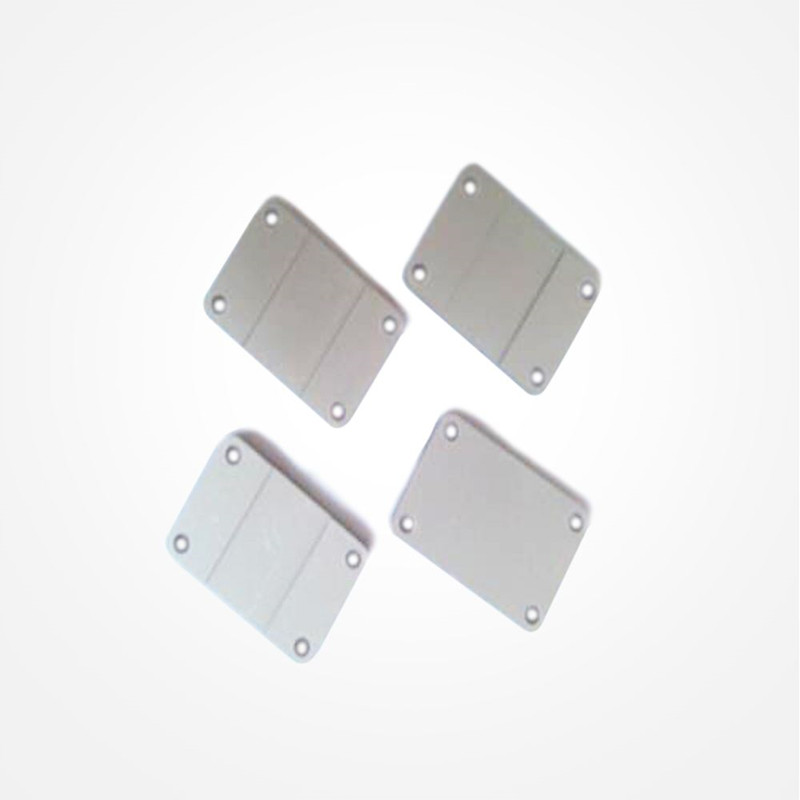

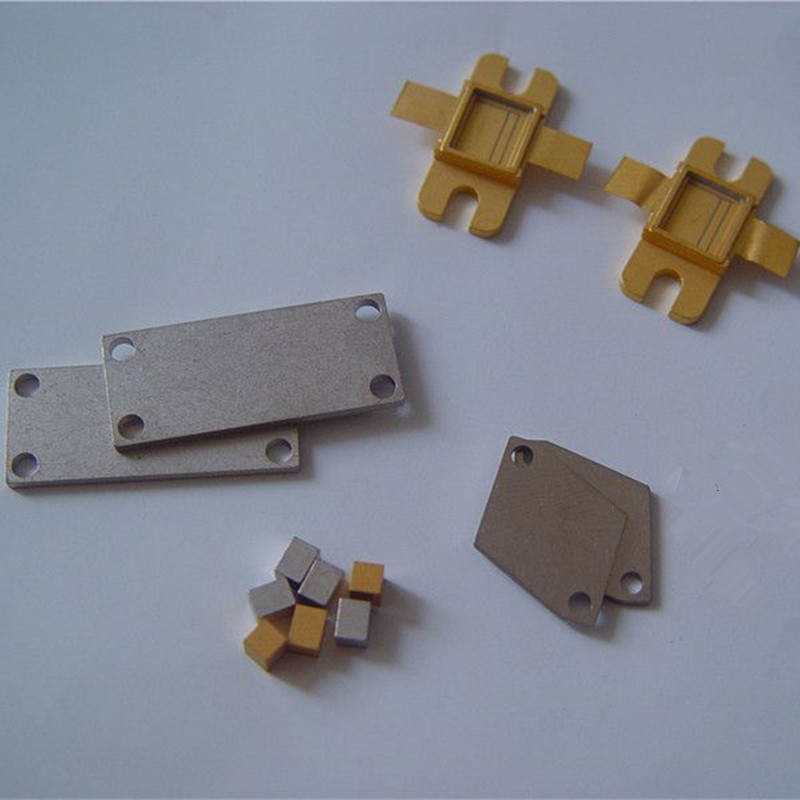

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Online Exporter Incoloy Material - CMC CuMoCu Heat Sink – Fotma , The product will supply to all over the world, such as: Canada, America, Uzbekistan, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.