Welcome to Fotma Alloy!

professional factory for Ptc Ceramic Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma

professional factory for Ptc Ceramic Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma Detail:

Description

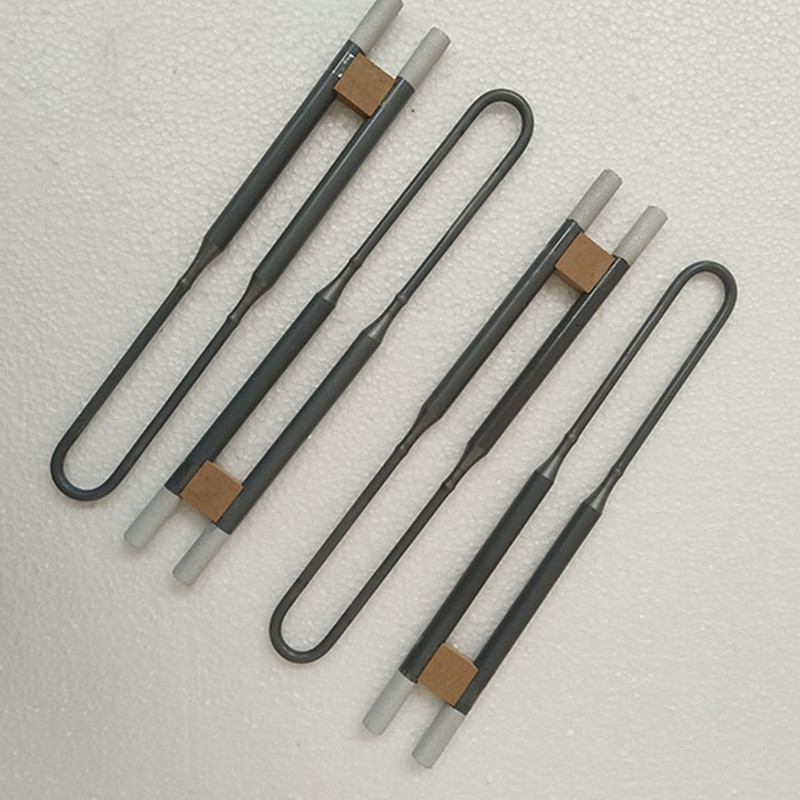

Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace

Furnace Heating Element

Standard Size for Electric MoSi2 Heater

M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

MoSi2 Heater Advantages

Technical Data of MoSi2 Heating Elements

| Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

| 5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

The Influence of Operation Temperature on the Heater Surface in Different Atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700 | 1800 |

| N2 | 1600 | 1700 |

| He | 1600 | 1700 |

| -80°C Dry H2 | 1150 | 1150 |

| -20°C Wet H2 | 1450 | 1450 |

| 10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined rate competiveness and good quality advantageous at the same time for professional factory for Ptc Ceramic Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma , The product will supply to all over the world, such as: Roman, Pakistan, Ghana, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Write your message here and send it to us