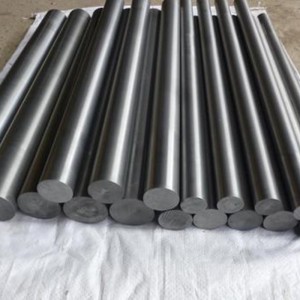

Pure Tungsten Rod Tungsten Bar

Purity 99.95% Tungsten Rods Tungsten Bars Brief Introduction

1. Standard: ASTM B760/ GB T3875.

2. Material Grade: W1.

3. Tungsten content: 99.95%.

4. Density: No less than 19.1g/cm3.

5. Size: 5.0mm~100mm diameter, Length: 50-1000mm.

6. Surface: Black, chemical cleaned or machined/ground.

7. Production capacity: 1000kg/month.

8. Applications of pure tungsten rod / tungsten bar: Pure tungsten rod/tungsten bar are generally used to manufacture emitting cathode, high temperature setting lever, support, lead, print needle and all kinds of electrodes and the quartz furnace heater.

Tungsten Properties

With melting point over 3000 degrees centigrade, tungsten is well known as a high performance material. Also it has low vapor pressure at elevated temperatures and low coefficient of thermal expansion. Tungsten material is widely in high temperature furnace components, lamp filament, electronic industry and other high temperature usages.

Pure Tungsten Rod / Tungsten Bar Production

Tungsten Rod / Tungsten Bar is produced with random lengths or customers' desired lengths by powder metallurgy method. Diameters can be made as per customers' requests. Tolerances can be made on request. Usually there are three different surface processes or finishes for customers' choice, depending on the different usages demand.

Pure Tungsten rod / Tungsten Bar Surface Finish

● Black - Surface is "as swaged" or "as drawn"; retaining a coating of processing lubricants and oxides.

● Cleaned - Surface is chemically cleaned to remove all lubricants and oxides.

● Ground - Surface is centerless ground to remove all coating and to achieve precise diameter control.

Pure Tungsten rod / Tungsten Bar Usages

Pure Tungsten rod / Tungsten Bar are widely used in illumination, heater and the electronic mechanical engineering, etc. Tungsten rods can be used in making the electricity photo source, the automobile and the tractor light bulb, make lattice side rod, framework, leading wire, electrode, heater and contact materials and so on.