Reasonable price Tantalum Bar - Tantalum Rod Tantalum Alloy Bar – Fotma

Reasonable price Tantalum Bar - Tantalum Rod Tantalum Alloy Bar – Fotma Detail:

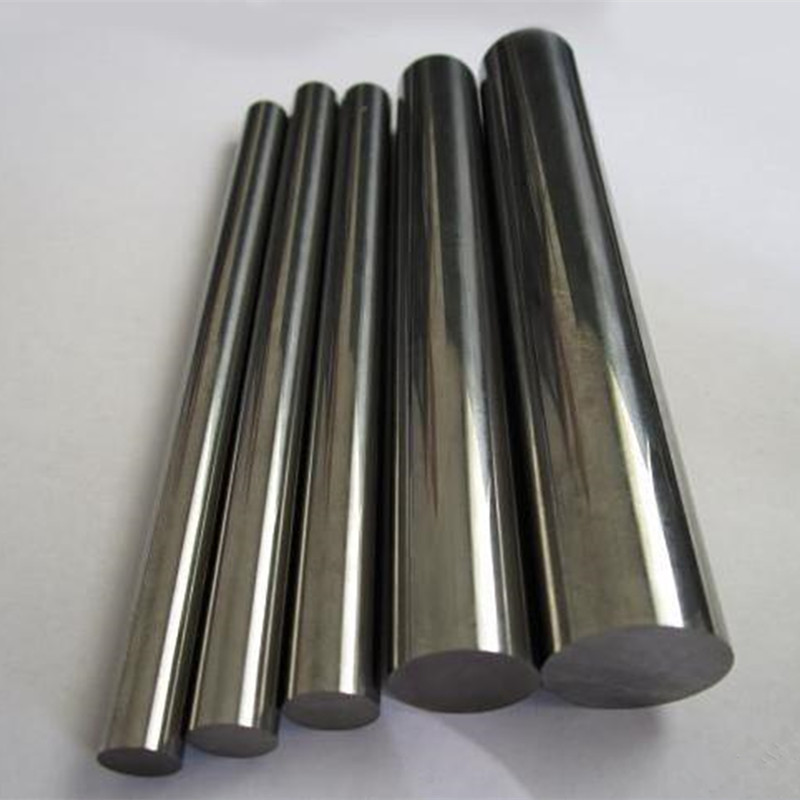

Applications of Tantalum Rods Tantalum Alloy Bar

Tantalum rods can be used to make heating parts and heat insulation parts for vacuum blast furnaces, in the chemical industry, it can be used to make digesters, heaters, coolers, various utensils, etc., as well as in the fields of aviation, aerospace industry, medical equipment, etc have a wide range of applications.

Tantalum rod Tantalum Alloy Bar Specification

Material Grade: R05200, R05400.

Standard: ASTM B365.

Tantalum Purity: ≥99.95%.

Production Process: cold rolling, pickling and shearing.

Technical Conditions: conform to GB/T14841-93, ASTM B365-92.

Specifications of tantalum rods: processed according to customer requirements.

Usage of tantalum rods: used to make heating parts and heat insulation parts for vacuum blast furnaces, and can be used to make digesters, heating parts in the chemical industry. It is widely used in aviation, aerospace industry, medical equipment and other fields.

| Tantalum Material Grade | Production Method | Diameter d(mm) | Tolerance (mm) | Length(mm) | Length Tolerance(mm) | ||

| Forged | Rolled | Ground or Machined | |||||

| Ta1Ta2FTa1

FTa2 R05200 R05400 R05255(Ta10W) R05252(Ta2.5W) Ta7.5W |

Ground, Machined, Cold Rolled, Cold Swaged, Forged | 3.0~4.5 | ±0.05 | ±0.05 | — | 500~1500 | ±5 |

| >4.5~6.5 | ±0.10 | ±0.10 | — | 500~1500 | ±5 | ||

| >6.5~10.0 | ±0.15 | ±0.15 | ±0.15 | 400~1500 | ±5 | ||

| >10~16 | ±1.5 | ±0.20 | ±0.2 | 300~1500 | ±5 | ||

| >16~18 | ±2.0 | — | ±0.2 | 200~1500 | ±20 | ||

| >18~25 | ±2.5 | — | ±0.3 | 200~1500 | ±20 | ||

| >25~40 | ±3.0 | — | ±0.4 | 150~1500 | ±20 | ||

| >40~50 | ±3.5 | — | ±0.5 | 100~1500 | ±20 | ||

| >50~65 | ±5.0 | — | ±0.6 | 100~1500 | ±20 | ||

| >65~200 | ±5.0 | — | ±0.8 | 100~1500 | ±20 | ||

Product detail pictures:

Related Product Guide:

We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Reasonable price Tantalum Bar - Tantalum Rod Tantalum Alloy Bar – Fotma , The product will supply to all over the world, such as: Costa Rica, Sweden, Iran, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.