Special Design for Machining Fabrication - Tungsten Copper WCu Heat Sink – Fotma

Special Design for Machining Fabrication - Tungsten Copper WCu Heat Sink – Fotma Detail:

Description

Tungsten copper electronic packaging material has both the low expansion properties of tungsten and the high thermal conductivity properties of copper. What is particularly valuable is that its thermal expansion coefficient and thermal conductivity can be designed by adjusting the composition of the material brought great convenience.

FOTMA uses high-purity and high-quality raw materials, and obtains WCu electronic packaging materials and heat sink materials with excellent performance after pressing, high-temperature sintering and infiltration.

Advantages of Tungsten Copper (WCu) Electronic Packaging Materials

1. The tungsten copper electronic packaging material has an adjustable thermal expansion coefficient, which can be matched with different substrates (such as: stainless steel, valve alloy, silicon, gallium arsenide, gallium nitride, aluminum oxide, etc.);

2. No sintering activation elements are added to maintain good thermal conductivity;

3. Low porosity and good air tightness;

4. Good size control, surface finish and flatness.

5. Provide sheet, formed parts, also can meet the needs of electroplating.

Copper Tungsten Heat Sink Properties

| Material Grade | Tungsten Content Wt% | Density g/cm3 | Thermal Expansion ×10-6 CTE(20℃) | Thermal Conductivity W/(M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCu | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Application of Tungsten Copper Heat Sinks

Materials suitable for packaging with high-power devices, such as substrates, lower electrodes, etc.; high-performance lead frames; thermal control boards and radiators for military and civilian thermal control devices.

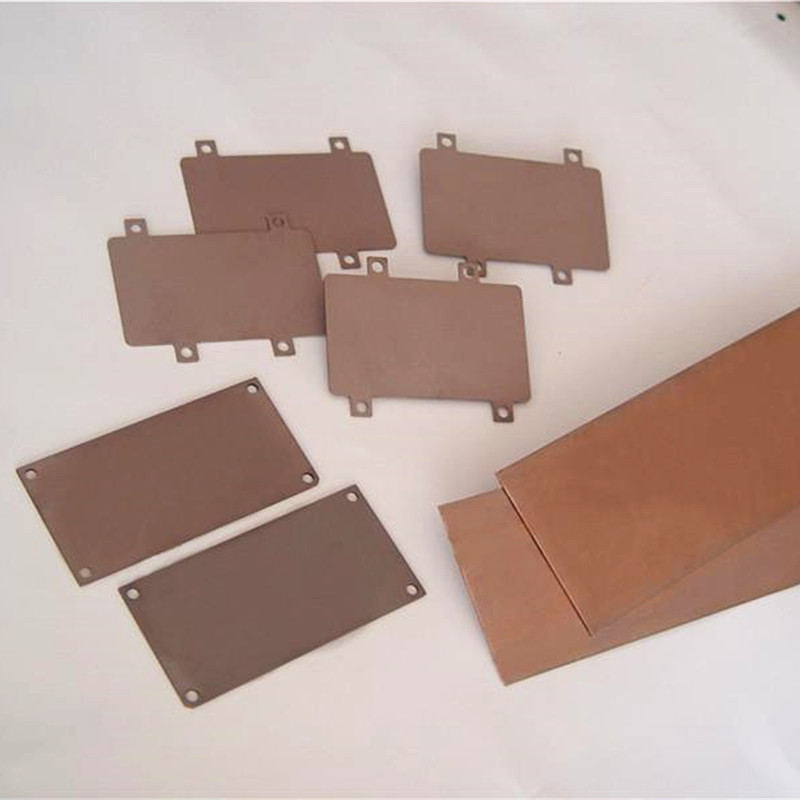

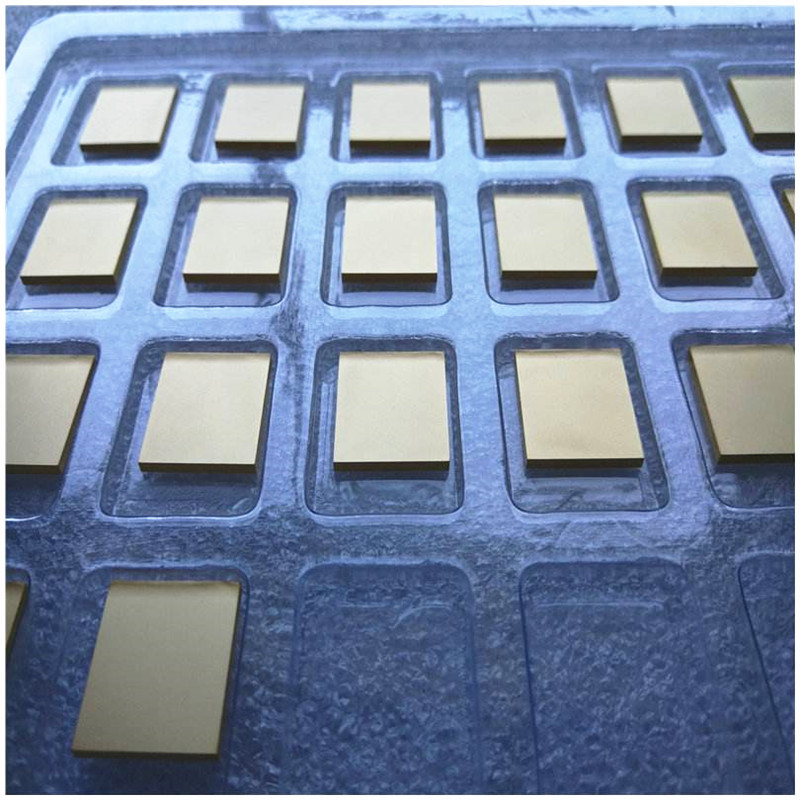

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Special Design for Machining Fabrication - Tungsten Copper WCu Heat Sink – Fotma , The product will supply to all over the world, such as: South Africa, Lesotho, Victoria, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.