Wholesale Dealers of Vmc Machined Components - Boron Nitride Ceramic Products – Fotma

Wholesale Dealers of Vmc Machined Components - Boron Nitride Ceramic Products – Fotma Detail:

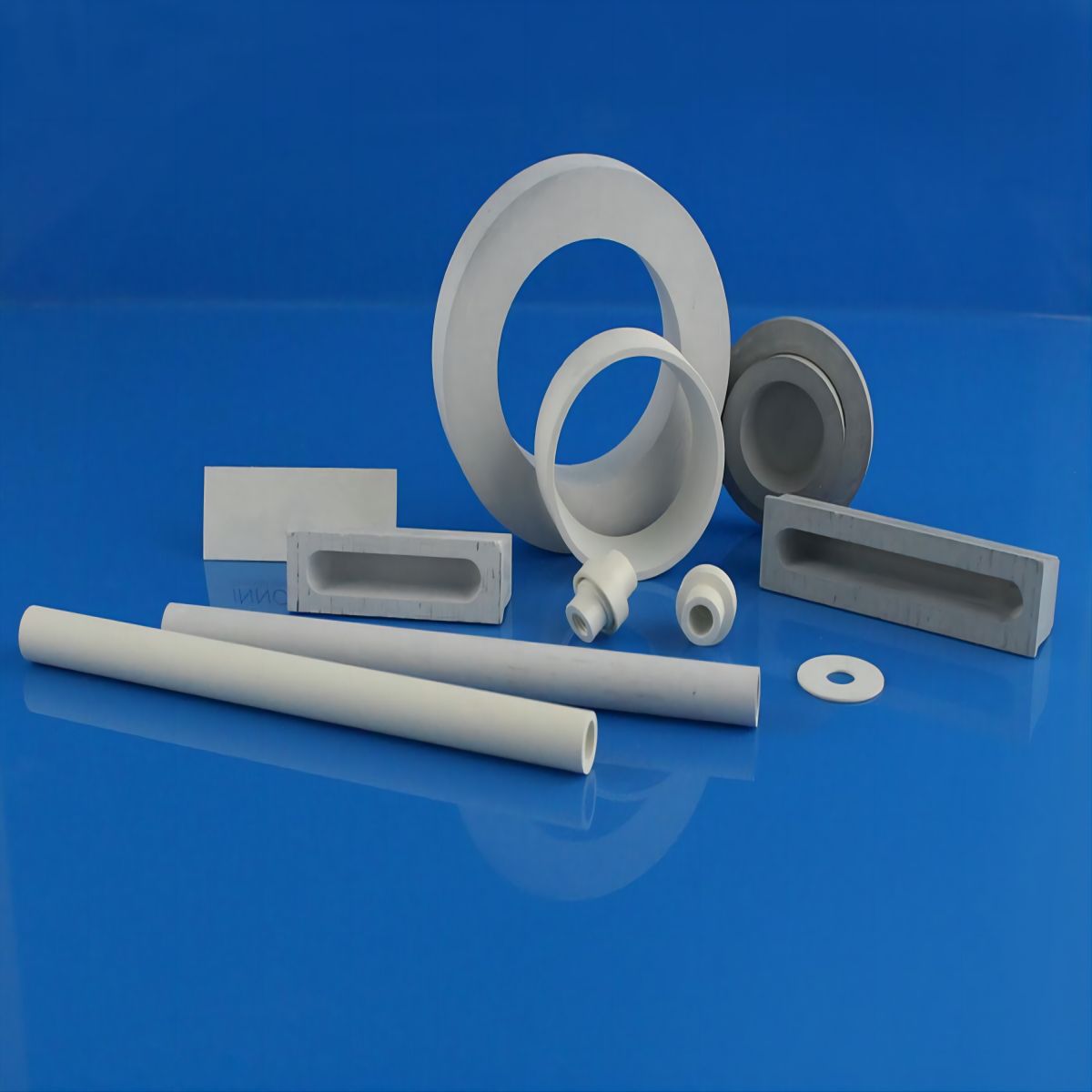

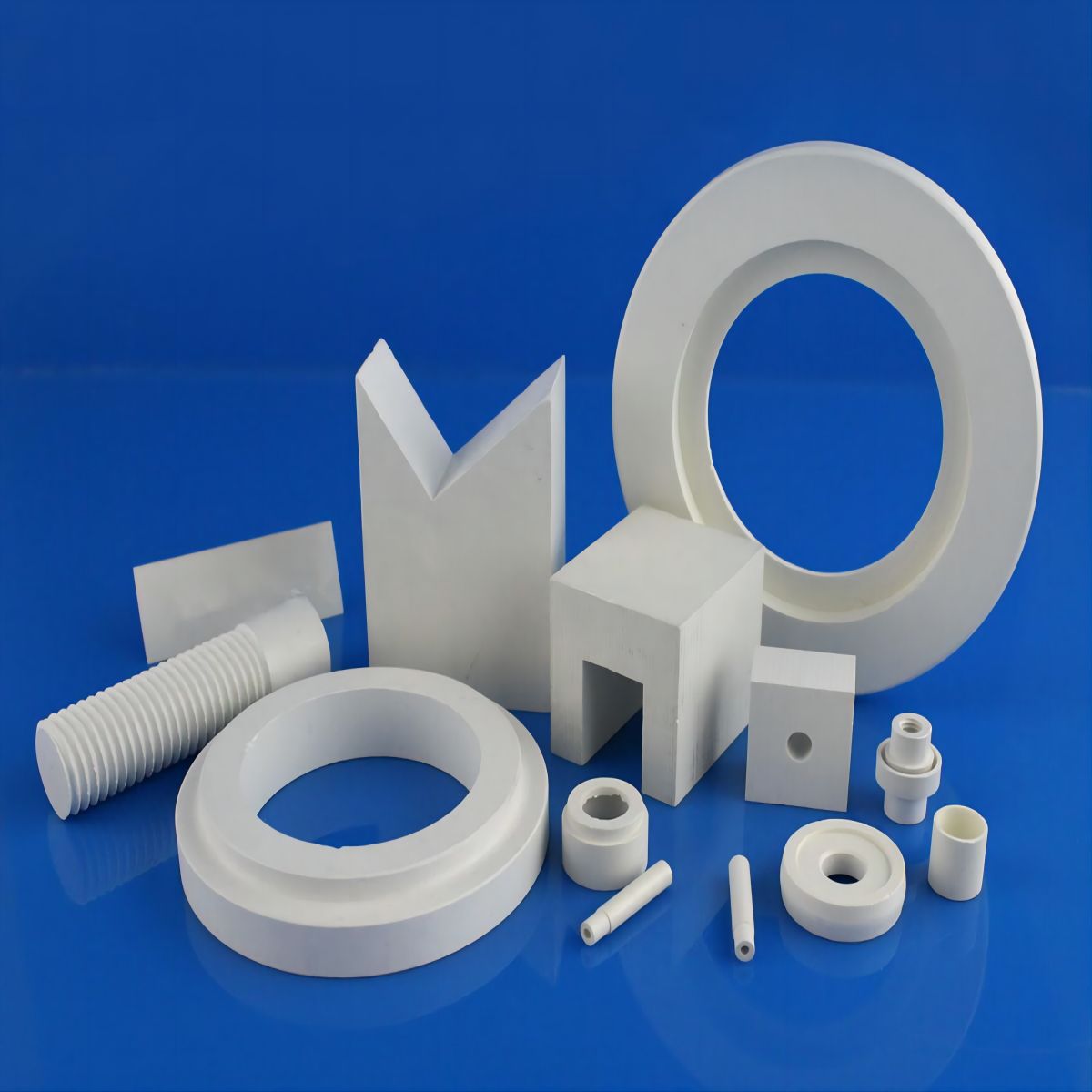

Introduction of boron nitride ceramic products

This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different binders, complete solutions, covering a variety of industry applications and customized profiles.

Boron Nitride Ceramic Applications

● High temperature furnace insulation parts, thermocouple protection tube.

● Amorphous nozzle and powder metal atomizing nozzle.

● High temperature mechanical components, such as bearings, valves and gaskets, etc.

● Molten metal crucible or mold.

● Horizontal continuous casting separation ring.

● Muffle kiln and crucible for nitride and Sialon firing.

● P-type diffusion source in the semiconductor industry.

● MOCVD regulator and its parts.

● Casting and rolling parts.

Features and Advantages of Boron Nitride Ceramic Products

1. Excellent high temperature resistance (use temperature can be ≥ 2000℃ under vacuum and inert atmosphere).

2. High thermal conductivity.

3. Excellent thermal shock resistance and low thermal expansion performance.

4. Excellent electrical insulation performance at high temperatur.

5. High resistance to molten metal, slag, glass.

6. High corrosion and wear resistance.

7. Easy to machine, can be processed according to needs to get the required shape and size.

Ceramic Products Processing Suggestions

Boron nitride ceramic materials have excellent machining properties and can be processed into complex shapes with very small tolerances as required. The following matters should be paid attention to in the processing of boron nitride ceramic materials:

Boron nitride ceramic materials can be processed with standard high-speed steel cutting tools. For the processing of harder PBN-E and composite materials, cemented carbide tools or diamond tools are recommended.

Grinding can be carried out as required, and standard taps and dies can be used to machine threads.

The machining process should always be kept dry, without the use of cutting oil and coolant.

Cutting tools should be sharp and clean, and do not use cutting tools with negative inclination.

When processing materials, be careful when jamming and clamping to avoid excessive pressure. Down-milling technology should be used to prevent missing edges and corners.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Wholesale Dealers of Vmc Machined Components - Boron Nitride Ceramic Products – Fotma , The product will supply to all over the world, such as: Brasilia, Buenos Aires, French, The president and all the company members would like to provide professional products and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!