Wholesale Discount Precision Machining Products - Tungsten Copper WCu Heat Sink – Fotma

Wholesale Discount Precision Machining Products - Tungsten Copper WCu Heat Sink – Fotma Detail:

Description

Tungsten copper electronic packaging material has both the low expansion properties of tungsten and the high thermal conductivity properties of copper. What is particularly valuable is that its thermal expansion coefficient and thermal conductivity can be designed by adjusting the composition of the material brought great convenience.

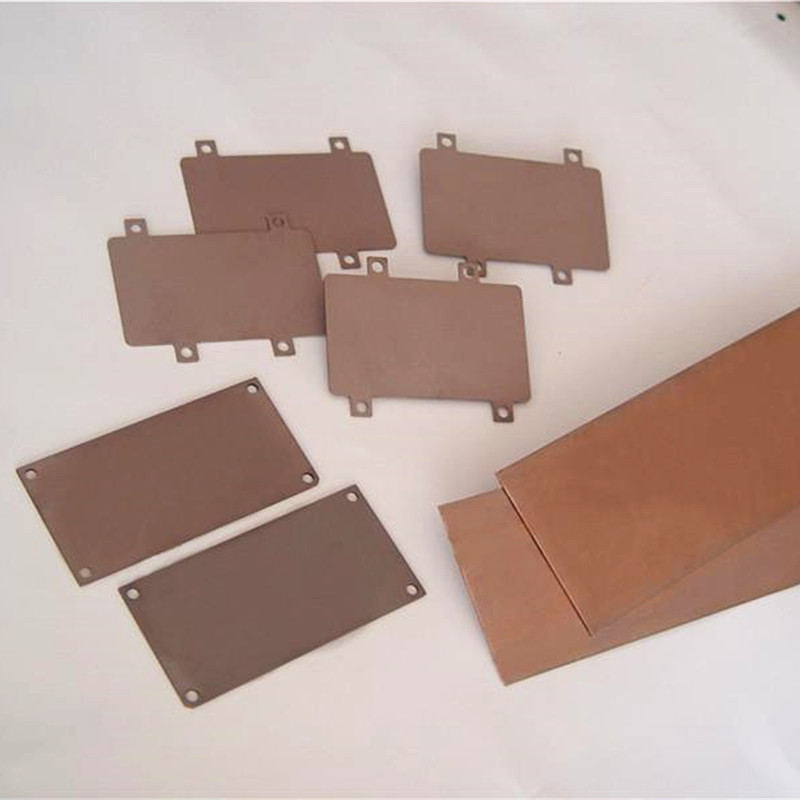

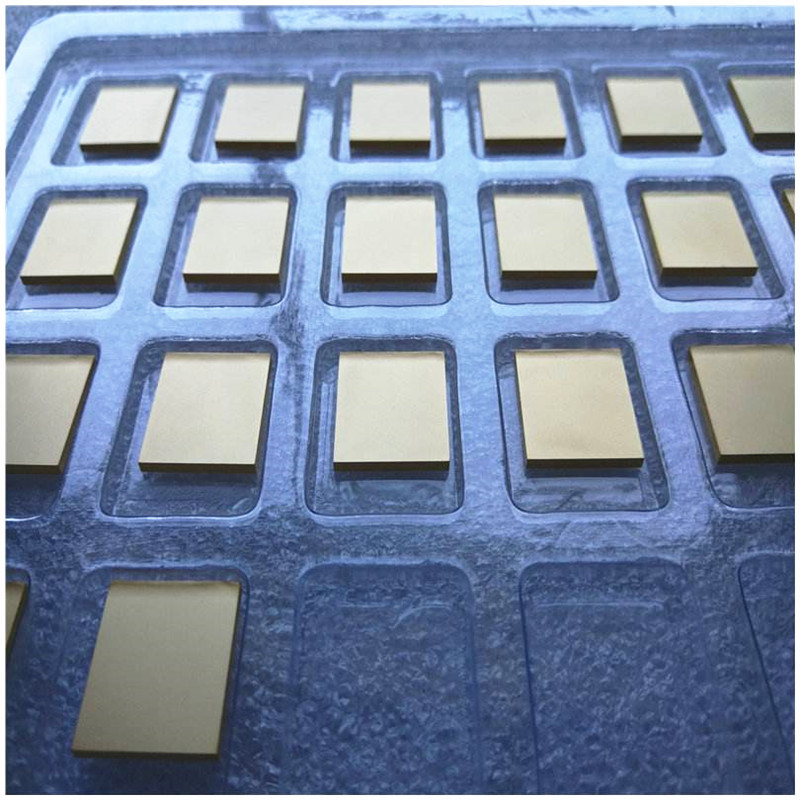

FOTMA uses high-purity and high-quality raw materials, and obtains WCu electronic packaging materials and heat sink materials with excellent performance after pressing, high-temperature sintering and infiltration.

Advantages of Tungsten Copper (WCu) Electronic Packaging Materials

1. The tungsten copper electronic packaging material has an adjustable thermal expansion coefficient, which can be matched with different substrates (such as: stainless steel, valve alloy, silicon, gallium arsenide, gallium nitride, aluminum oxide, etc.);

2. No sintering activation elements are added to maintain good thermal conductivity;

3. Low porosity and good air tightness;

4. Good size control, surface finish and flatness.

5. Provide sheet, formed parts, also can meet the needs of electroplating.

Copper Tungsten Heat Sink Properties

| Material Grade | Tungsten Content Wt% | Density g/cm3 | Thermal Expansion ×10-6 CTE(20℃) | Thermal Conductivity W/(M·K) |

| 90WCu | 90±2% | 17.0 | 6.5 | 180 (25℃) /176 (100℃) |

| 85WCu | 85±2% | 16.4 | 7.2 | 190 (25℃)/ 183 (100℃) |

| 80WCu | 80±2% | 15.65 | 8.3 | 200 (25℃) / 197 (100℃) |

| 75WCu | 75±2% | 14.9 | 9.0 | 230 (25℃) / 220 (100℃) |

| 50WCu | 50±2% | 12.2 | 12.5 | 340 (25℃) / 310 (100℃) |

Application of Tungsten Copper Heat Sinks

Materials suitable for packaging with high-power devices, such as substrates, lower electrodes, etc.; high-performance lead frames; thermal control boards and radiators for military and civilian thermal control devices.

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for Wholesale Discount Precision Machining Products - Tungsten Copper WCu Heat Sink – Fotma , The product will supply to all over the world, such as: Namibia, Germany, Macedonia, Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!